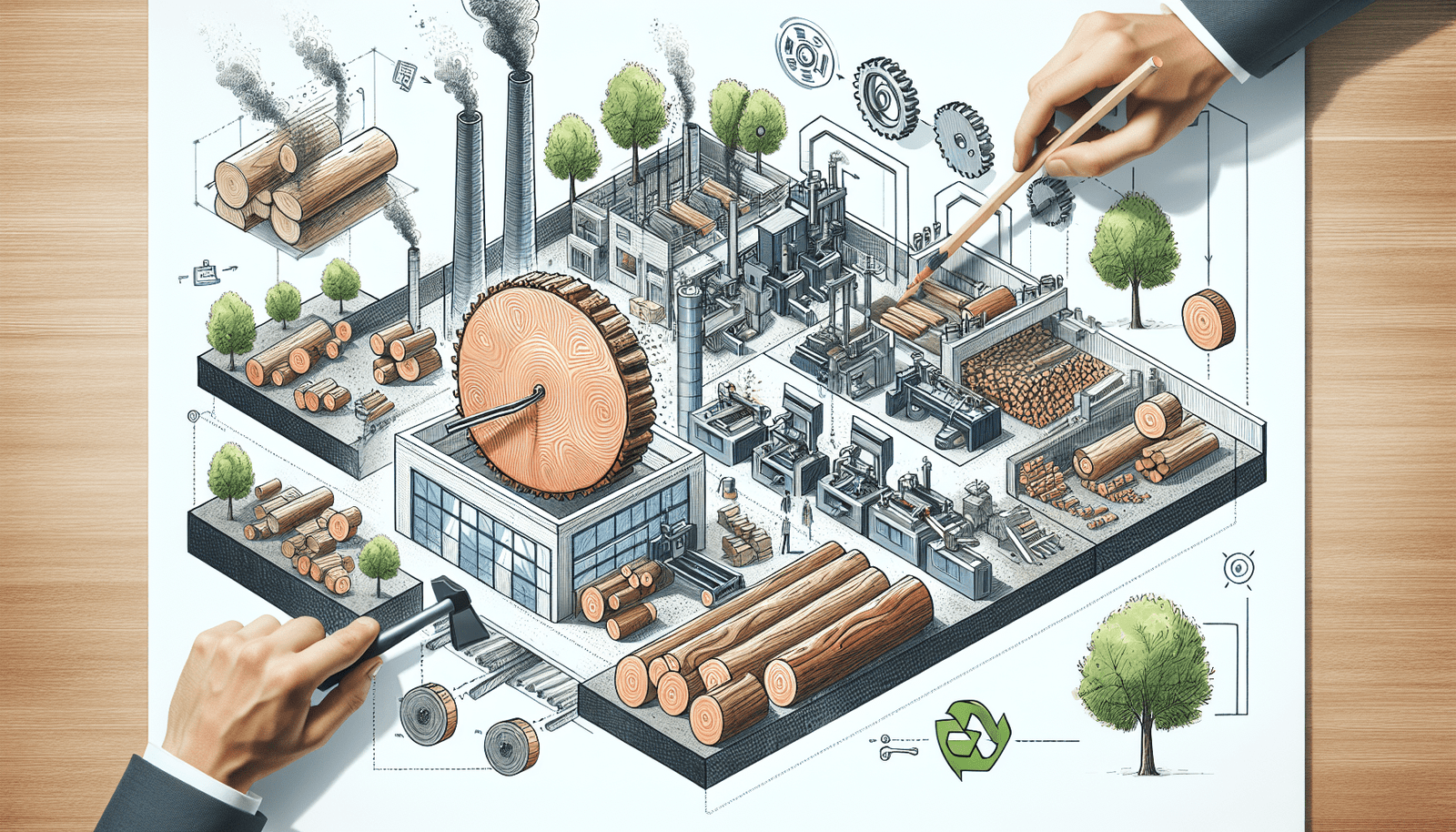

Are you looking for ways to minimize wood wastage? In this article, we will explore various strategies and techniques that can help you reduce the amount of wood that goes to waste. From efficient cutting and manufacturing processes to recycling and repurposing methods, you will discover practical solutions to make the most out of every piece of wood. Whether you are a woodworking enthusiast or a professional in the industry, these tips will not only help you reduce wastage but also lower costs and promote sustainability. So, let’s delve into the world of wood conservation together and unlock the secrets of minimizing wastage!

Proper Planning and Design

Use accurate measurements and calculations

When it comes to reducing wood wastage, proper planning and design are key. This starts with using accurate measurements and calculations. Ensuring that you have precise dimensions for your project can help minimize errors and reduce the amount of wasted wood. Take the time to carefully measure and double-check your calculations before starting any cutting or construction.

Minimize material waste through efficient design

Another factor to consider in reducing wood wastage is efficient design. By optimizing the layout and structure of your project, you can minimize the amount of material that goes to waste. This can be achieved by carefully planning how to cut the pieces from your chosen materials, making efficient use of each board or sheet. By being mindful of the design and layout, you can make the most of your materials and minimize waste.

Consider alternative materials or methods

In addition to accurate measurements and efficient design, considering alternative materials or methods can also help reduce wood wastage. Some projects may be suitable for using engineered wood products, which often come in precise sizes and eliminate the need for cutting and shaping conventional lumber. Additionally, exploring alternative construction techniques, such as modular or prefabricated elements, may offer opportunities to reduce waste and optimize resource usage.

Efficient Woodcutting Techniques

Using appropriate sawing techniques

Efficient woodcutting techniques are crucial for minimizing waste. One key aspect is using appropriate sawing techniques. Different types of saw cuts, such as rip cuts and crosscuts, produce varying amounts of waste. Understanding which type of cut is most suitable for each piece of wood can help maximize the usable material and minimize offcuts. It is also important to ensure that the saw blade is sharp, as dull blades can result in splintering and diminished cutting precision.

Optimizing board sizes and cuts

To further reduce waste, optimizing board sizes and cuts is essential. Careful planning and consideration should go into determining the most efficient way to cut each piece from the available boards. By strategically arranging and organizing the cuts, you can minimize the amount of unused wood that ends up as waste. This requires thoughtful decision-making and often involves creating a cutting plan before starting the actual work.

Utilizing a computer-aided design (CAD) program

Leveraging technology, such as computer-aided design (CAD) programs, can greatly enhance woodcutting efficiency. CAD software allows you to create detailed 2D or 3D models of your project, enabling you to visualize and plan the most efficient use of materials. With accurate measurements and virtual representations of the project, CAD programs help optimize board sizes and cuts, reducing wastage. Additionally, CAD software can provide precise cutting diagrams, ensuring that you can make the most of each piece of wood.

Material Optimization Strategies

Nesting and panel optimization

Nesting and panel optimization techniques are effective strategies for reducing wood wastage, particularly in projects that involve cutting large panels or sheets. Nesting refers to arranging the individual shapes or components of a project in a way that maximizes the use of available materials. By carefully nesting the pieces, you can minimize unused space and optimize the number of parts that can be obtained from each panel or sheet. Panel optimization software can aid in this process by automatically generating the most efficient nesting patterns.

Utilizing offcuts and scraps

Utilizing offcuts and scraps is another excellent method of reducing wood wastage. Instead of discarding small pieces of wood that may not fit in your project, consider repurposing them for smaller components or using them in other projects altogether. Offcuts can often be combined or transformed into useful items such as cutting boards, coasters, or even decorative accents. By finding creative ways to make use of these leftover pieces, you not only reduce waste but also unlock the potential for unique and resourceful craftsmanship.

Implementing lean manufacturing principles

Implementing lean manufacturing principles can drive efficiency and minimize wood wastage. Derived from the Toyota Production System, lean manufacturing focuses on eliminating waste, maximizing value, and continuously improving processes. By implementing lean principles in your woodworking projects, you can identify and eliminate any unnecessary steps or activities that may lead to waste. This approach encourages constant evaluation and adaptation to optimize the use of materials, reduce excess inventory, and enhance overall productivity.

Use of Timber and Wood Products

Sourcing sustainable and certified wood

When it comes to the use of timber and wood products, sourcing sustainably and certified wood is essential for responsible and environmentally conscious woodworking. Look for wood that comes from sustainable forestry practices, such as those certified by organizations like the Forest Stewardship Council (FSC). These organizations ensure that the wood is harvested in a way that maintains the health and biodiversity of forests, as well as the rights of local communities. By choosing sustainable wood, you are not only reducing wastage but also supporting ethical and environmentally friendly practices.

Choosing engineered wood products

Engineered wood products, such as laminated veneer lumber (LVL) or oriented strand board (OSB), offer several advantages in terms of reducing wood wastage. These products are manufactured using thin layers or strands of wood, allowing for precise sizing and reducing the need for excessive cutting or shaping. Additionally, engineered wood products often come in large, standardized panels or beams, minimizing waste from offcuts. By incorporating engineered wood products into your projects, you can reduce both material waste and the impact on natural forests.

Buying reclaimed or salvaged wood

An alternative to using new timber is buying reclaimed or salvaged wood. Reclaimed wood refers to lumber that has been recycled or salvaged from old buildings, barns, or other structures. Using reclaimed wood not only reduces the demand for new timber but also gives a second life to wood that would otherwise be wasted. Reclaimed wood can add character and uniqueness to your projects, as each piece may bear the marks and history of its previous use. By purchasing and repurposing reclaimed wood, you contribute to waste reduction while creating one-of-a-kind pieces.

Implementing Waste Reduction Practices

Recycling and reusing wood waste

One of the most effective ways to reduce wood wastage is by implementing recycling and reusing practices for wood waste. Any leftover or unused wood can be repurposed for various purposes. Small offcuts can be reused for crafts or as fuel material for heating or cooking. Larger wood waste can be sent to wood recycling centers that repurpose the material for mulch, compost, or even new wood products. By actively recycling and reusing wood waste, you divert it from landfills and contribute to a more sustainable and circular economy.

Implementing a waste management plan

To ensure consistent and efficient waste reduction, implementing a waste management plan is crucial. This plan should outline the specific steps and strategies for managing wood waste throughout your woodworking processes. It should include guidelines for segregation, storage, and disposal of different types of wood waste. Additionally, the plan should detail any recycling or reusing initiatives, as well as the necessary infrastructure or partnerships to support these efforts. By having a solid waste management plan in place, you can systematically address the issue of wood wastage and continually improve your practices.

Training staff on waste reduction practices

Efficient waste reduction practices require the involvement and commitment of everyone involved in the woodworking process. Training your staff on waste reduction practices is therefore essential. Educate your team on the importance of minimizing wood wastage and provide them with the necessary knowledge and skills to implement waste reduction strategies. This may include training on accurate measurements, efficient cutting techniques, and the proper handling and disposal of wood waste. By empowering your staff with the necessary tools, you create a culture of waste reduction and foster a more sustainable woodworking environment.

Responsibly Disposing of Wood Waste

Complying with local regulations and guidelines

When it comes to responsibly disposing of wood waste, it is imperative to comply with local regulations and guidelines. Check with your local authorities to understand the specific requirements for handling and disposing of wood waste. This may include regulations on waste segregation, maximum quantities allowed for disposal, or the need for special permits or licenses. By adhering to these regulations, you ensure that your woodworking activities are conducted in an environmentally responsible manner.

Utilizing wood waste for energy production

Wood waste can also be utilized for energy production, rather than simply disposing of it. Certain types of wood waste, such as sawdust or wood shavings, can be used as biomass fuel for heating or power generation. This process, known as “wood waste-to-energy,” allows for the conversion of wood waste into a valuable resource. By harnessing the energy potential of wood waste, you not only reduce landfill usage but also contribute to renewable energy production and promote a more sustainable energy mix.

Collaborating with local recycling facilities

Collaborating with local recycling facilities is another way to responsibly dispose of wood waste. Many recycling centers or wood reclamation organizations specialize in collecting and repurposing wood waste. Reach out to these facilities to explore partnership opportunities and inquire about their acceptance criteria and processes. By establishing a relationship with local recycling facilities, you can ensure that your wood waste is properly managed and recycled into new products or materials, minimizing its impact on the environment.

Educating and Raising Awareness

Promoting the importance of wood waste reduction

Educating and raising awareness about the importance of wood waste reduction is crucial for fostering a more sustainable woodworking industry. Promote the benefits of waste reduction within your own woodworking community by sharing success stories, case studies, and best practices. Highlight the environmental, economic, and social advantages of minimizing wood wastage, such as cost savings, resource conservation, and reduced impact on forests. By actively advocating for wood waste reduction, you contribute to a collective effort to create a more sustainable future.

Providing training and resources to industry professionals

In addition to promoting awareness, providing training and resources to industry professionals is essential for driving widespread adoption of wood waste reduction practices. Offer workshops, seminars, or online courses on topics such as efficient woodworking techniques, material optimization strategies, or waste management principles. Create resources, such as guides, e-books, or videos, that provide practical tips and techniques for minimizing wood wastage. By equipping professionals with the knowledge and skills necessary for waste reduction, you empower them to make a positive impact in their own woodworking endeavors.

Engaging in community outreach and education

Engaging in community outreach and education initiatives can further amplify the message of wood waste reduction. Collaborate with local schools, community centers, or environmental organizations to organize workshops or demonstrations focused on sustainable woodworking practices. Share your expertise and experience with aspiring woodworkers or those interested in sustainable construction. By actively engaging with the broader community, you not only inspire others to adopt waste reduction practices but also contribute to a collective effort to create a more environmentally conscious society.

Collaborating with Suppliers and Contractors

Working with suppliers focused on waste reduction

Collaborating with suppliers that share your commitment to waste reduction is crucial for creating a more sustainable supply chain. Prioritize suppliers who demonstrate environmentally friendly practices and offer materials with minimal packaging or waste. Communication is key in establishing a partnership focused on waste reduction, so engage in open and transparent discussions with suppliers about your expectations and sustainability goals. By working together, you can collectively minimize the environmental impact of the woodworking industry and drive positive change throughout the entire value chain.

Choosing contractors with sustainable practices

When working on larger projects that involve contractors, selecting those with sustainable practices is essential for reducing wood wastage. Partner with contractors who prioritize waste reduction and adhere to responsible woodworking techniques. Seek out contractors who have experience in efficient woodcutting, material optimization, and waste management. Request references or examples of their previous projects to ensure that they align with your waste reduction objectives. By carefully choosing contractors with sustainable practices, you can ensure that your projects are executed with minimal environmental impact.

Encouraging transparency and accountability

Encouraging transparency and accountability throughout your supply chain is vital for achieving meaningful wood waste reduction. Communicate your sustainability goals and expectations to suppliers and contractors, and request regular updates on their waste reduction efforts. Transparency allows you to track progress, identify areas for improvement, and celebrate successes. By holding all stakeholders accountable for their waste reduction practices, you create a culture of responsibility and foster a more sustainable woodworking industry.

Adopting Sustainable Manufacturing Processes

Implementing efficient production methods

Adopting sustainable manufacturing processes entails implementing efficient production methods. Optimize your production line by analyzing each step and identifying opportunities for waste reduction. Streamline workflows to minimize unnecessary movements or handling of materials. Integrate production planning and scheduling to ensure the right amount of materials are used for each project. By continuously evaluating and improving your production methods, you can maximize efficiency and minimize wastage throughout the manufacturing process.

Reducing energy consumption

Reducing energy consumption is a fundamental aspect of sustainable manufacturing. Evaluate your energy usage and identify areas where efficiency improvements can be made. Consider investing in energy-efficient machinery or equipment, such as low-energy consumption lighting or woodworking tools. Implement practices such as proper insulation, energy-saving settings, and regular maintenance to optimize energy efficiency. By minimizing energy consumption, you not only reduce environmental impact but also potentially lower operational costs.

Using eco-friendly finishing techniques

The finishing stage of woodworking often involves the use of chemicals and coatings that can have adverse environmental effects. To adopt sustainable manufacturing processes, explore eco-friendly finishing techniques and materials. Look for low-VOC (volatile organic compound) or water-based finishes that have reduced environmental impact. Consider alternative natural finishes, such as oils or waxes, which are typically more environmentally friendly than traditional varnishes or lacquers. By choosing eco-friendly finishing techniques, you can minimize the release of harmful substances and contribute to a healthier and more sustainable woodworking industry.

Evaluating and Monitoring Progress

Conducting regular waste audits

To ensure continuous improvement in wood waste reduction, conducting regular waste audits is crucial. Regularly assess the amount and type of waste generated throughout your woodworking processes. Analyze trends, identify areas of improvement, and set targets for waste reduction. Waste audits allow you to measure the effectiveness of your waste reduction strategies, track progress over time, and make informed decisions on implementing further improvements. By regularly evaluating your waste management practices, you can refine your woodworking processes and achieve greater sustainability.

Tracking and analyzing wood waste data

Tracking and analyzing wood waste data goes hand in hand with conducting waste audits. Establish a system to record and monitor key waste metrics such as quantities, types, and sources of wood waste. Use this data to identify patterns, spot areas of inefficiency, and inform decision-making. By analyzing wood waste data, you can uncover insights that guide future steps in waste reduction. This data-driven approach allows you to make evidence-based decisions and evaluate the impact of your efforts in a quantifiable manner.

Continuously improving waste reduction strategies

Lastly, continuous improvement should be at the heart of your wood waste reduction efforts. Building on the knowledge gained from waste audits and data analysis, continuously refine and update your waste reduction strategies. Stay updated on industry best practices and new technologies that may offer additional opportunities for waste minimization. Foster a culture of innovation and collaboration, encouraging input from your team and other stakeholders involved in the woodworking process. By prioritizing continuous improvement, you can ensure that your wood waste reduction efforts remain effective and impactful in the long run.

Hi, I’m James Gheen, the creator behindWoodRebirth.com. As someone passionate about sustainability and environmental stewardship, I created this pioneering online platform to change how we approach wood waste and pallet disposal. Through detailed recycling and disposal guides, creative DIY projects, and upcycling inspirations, I aim to inspire individuals and businesses to adopt eco-friendly practices in their wood waste management. At WoodRebirth.com, we foster a vibrant community focused on education and engagement, encouraging the sharing of ideas and success stories. Join me in our mission to give wood waste a new lease on life, making a tangible impact on our environment, one pallet at a time.