Have you ever wondered how to determine if a pallet is treated? It’s not as complicated as it may seem! In this article, we will explore a few simple indicators that can help you determine if a pallet has been treated or not. By understanding these signs, you can ensure the safety and quality of the pallets you use in your projects or business. So, let’s jump right in and discover the telltale signs of treated pallets!

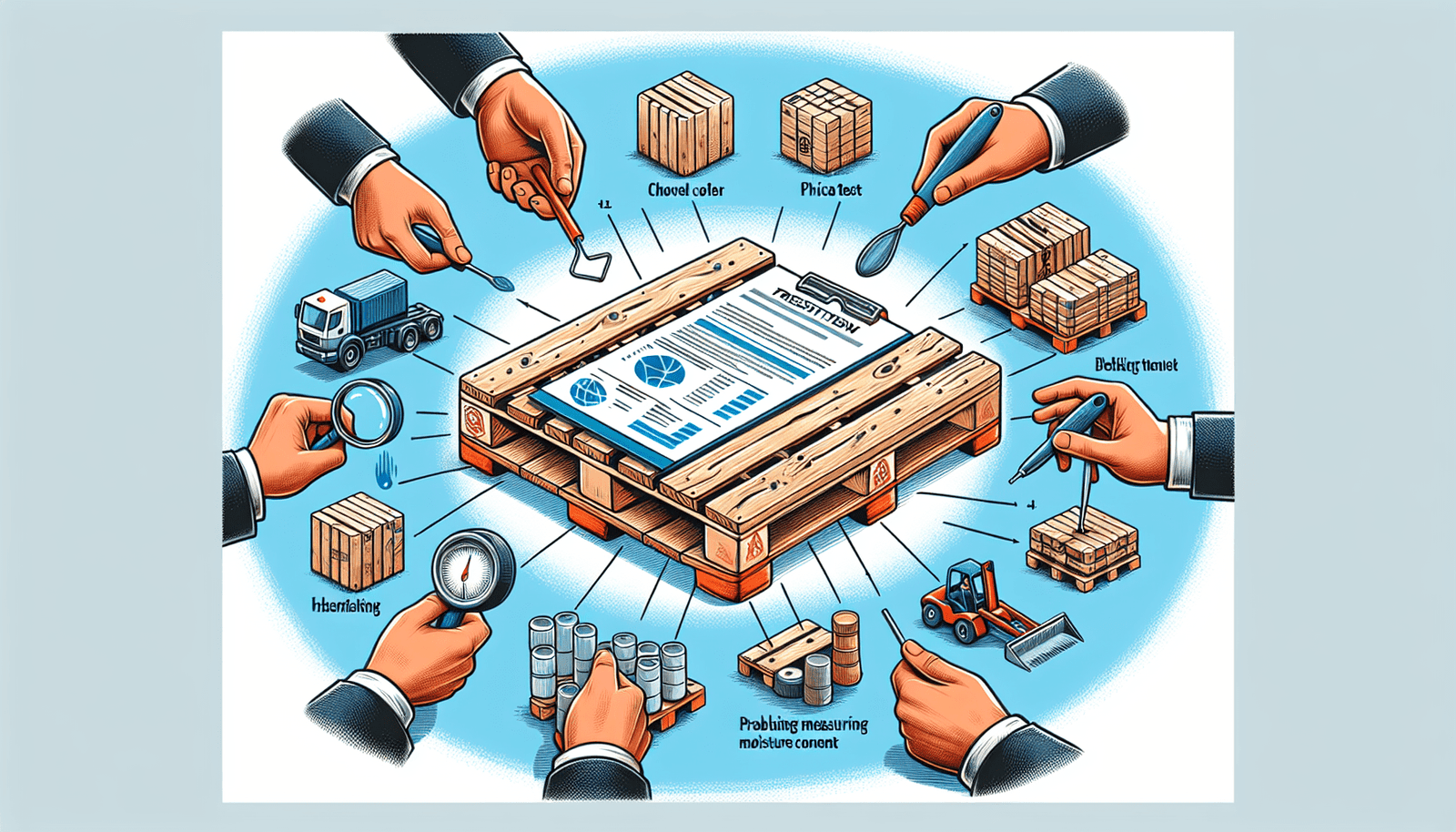

Visual Inspection

When inspecting a pallet, there are several visual cues that can indicate whether or not it has been treated. One of the first things to look for is the color of the wood. Treated pallets often have a darker, more uniform color compared to untreated ones. This is because the treatment process involves applying chemicals to the wood, which can alter its natural color.

Another important aspect to consider during a visual inspection is the texture of the wood. Treated pallets tend to have a smoother surface compared to untreated ones. This is due to the chemicals used in the treatment process, which can penetrate the wood and create a more polished appearance.

Presence of stamps is another indication of a pallet being treated. Look for stamps or markings on the pallet, as they often indicate that it has gone through a treatment process. These stamps can vary depending on the country and treatment method, but they typically include information such as the type of treatment, the treatment facility, and the treatment date.

Similarly, labels can provide valuable information about the pallet’s treatment status. Check for labels that indicate the use of treated wood or specify the treatment method used. These labels are usually placed on the side or top of the pallet and can help you determine if the pallet has been properly treated.

Odor

In addition to visual cues, the odor of the pallet can also provide insights into its treatment status. Treated pallets may have a distinct chemical smell, which is often the result of the chemicals used in the treatment process. If you detect a strong chemical odor when inspecting a pallet, it is likely that it has been treated. However, it’s important to note that not all treated pallets will have a noticeable odor, especially if the treatment was done some time ago.

Wood Type

Differentiating between softwood and hardwood pallets is another way to determine if a pallet has undergone treatment. Softwood pallets, which are typically made from pine or spruce, are more commonly treated due to their susceptibility to decay and insect damage. On the other hand, hardwood pallets, such as oak or maple, are more resistant to these issues and are less likely to be treated.

It is also helpful to familiarize yourself with the common wood types used for pallets. By knowing the characteristics of different woods, you can make a better judgment about whether or not a pallet has been treated. For example, oak pallets are known for their durability and resistance to moisture, while pine pallets are more prone to decay and require treatment to prolong their lifespan.

Manufacturer Markings

Certain markings or stamps on a pallet can provide valuable information regarding its treatment status. Two common markings to look out for are the ISPM 15 logo and the HT stamp.

The ISPM 15 logo, which stands for International Standards for Phytosanitary Measures No. 15, indicates that the pallet has been treated in accordance with international regulations for preventing the spread of pests and diseases. This treatment typically involves heat treatment or fumigation and is mandatory for pallets used in international shipping. If a pallet has the ISPM 15 logo, it is a clear indication that it has undergone a treatment process.

The HT stamp, on the other hand, stands for “Heat Treated.” This stamp indicates that the pallet has been heat-treated to eliminate pests and reduce moisture content. Heat treatment is one of the most common methods used to treat pallets, and the presence of an HT stamp confirms that the pallet has undergone this process.

Moisture Content

The moisture content of a pallet can also provide clues about its treatment status. Treated pallets are typically dried to a specific moisture level to prevent fungal growth and improve the longevity of the wood. To determine the moisture content of a pallet, you can use a moisture meter, which measures the amount of moisture within the wood.

By measuring the moisture content, you can compare the results to recommended levels for treated pallets. In general, treated pallets should have a moisture content below 20%, as higher moisture levels can indicate insufficient treatment or the presence of excess moisture that could lead to decay or insect infestation.

Treatment Certifications

When inspecting a pallet, it is important to verify any documentation regarding its treatment status. This can include treatment certificates or invoices from the supplier, which provide proof that the pallet has been treated. Take the time to review these documents and ensure that they correspond to the pallet in question. The absence of proper documentation may indicate that the pallet has not been treated or that the treatment was not done according to established standards.

Usage History

Examining the usage history of a pallet can also provide insights into its treatment status. One way to gather this information is by asking the supplier or previous users about the pallet’s history. They may be able to provide details about any treatments the pallet has undergone or its previous applications.

Another way to inspect the usage history is by examining the pallet itself. Look for signs of wear and tear that indicate the pallet has been used extensively. If you notice any repairs or stains on the wood, it could suggest that the pallet has had a previous life and may or may not have been treated during that time. However, it’s important to keep in mind that the absence of visible signs does not necessarily mean the pallet has not been treated.

Chemical Testing

For a more conclusive determination of a pallet’s treatment status, professional laboratory analysis can be conducted. This involves collecting samples from the pallet and analyzing them for the presence of treatment chemicals. Chemical testing can provide accurate results and is particularly useful when dealing with large quantities of pallets or when there is uncertainty about their treatment status.

However, it’s worth noting that chemical testing can be time-consuming and costly. Therefore, it is often reserved for situations where a definitive answer is needed or when legal or regulatory compliance is a concern.

Online Resources

If you’re interested in learning more about pallet treatment, there are several websites and forums dedicated to this topic. These online resources can provide valuable information, tips, and discussions from experts in the industry. By exploring these platforms, you can gain a deeper understanding of pallet treatment methods, regulations, and best practices.

Seek Professional Advice

When in doubt about the treatment status of a pallet, it is always wise to seek professional advice from pallet experts or inspectors. These professionals have the knowledge and experience to accurately assess a pallet’s treatment status and can provide guidance on handling and using pallets safely.

Pallet experts can conduct thorough inspections, perform laboratory analysis if necessary, and help you navigate the complexities of pallet treatment regulations. Their expertise can save you time and effort while ensuring that you are using treated pallets that meet the required standards.

In conclusion, determining whether a pallet has been treated involves a combination of visual inspection, odor assessment, knowledge of wood types, examination of markings, inspection of moisture content, verification of treatment certifications, examination of usage history, and potentially chemical testing. By utilizing these methods and seeking advice from professionals, you can effectively determine the treatment status of a pallet and make informed decisions regarding its use. Remember, ensuring the safety and compliance of your pallets is crucial to protect your products, your business, and the environment.

Hi, I’m James Gheen, the creator behindWoodRebirth.com. As someone passionate about sustainability and environmental stewardship, I created this pioneering online platform to change how we approach wood waste and pallet disposal. Through detailed recycling and disposal guides, creative DIY projects, and upcycling inspirations, I aim to inspire individuals and businesses to adopt eco-friendly practices in their wood waste management. At WoodRebirth.com, we foster a vibrant community focused on education and engagement, encouraging the sharing of ideas and success stories. Join me in our mission to give wood waste a new lease on life, making a tangible impact on our environment, one pallet at a time.